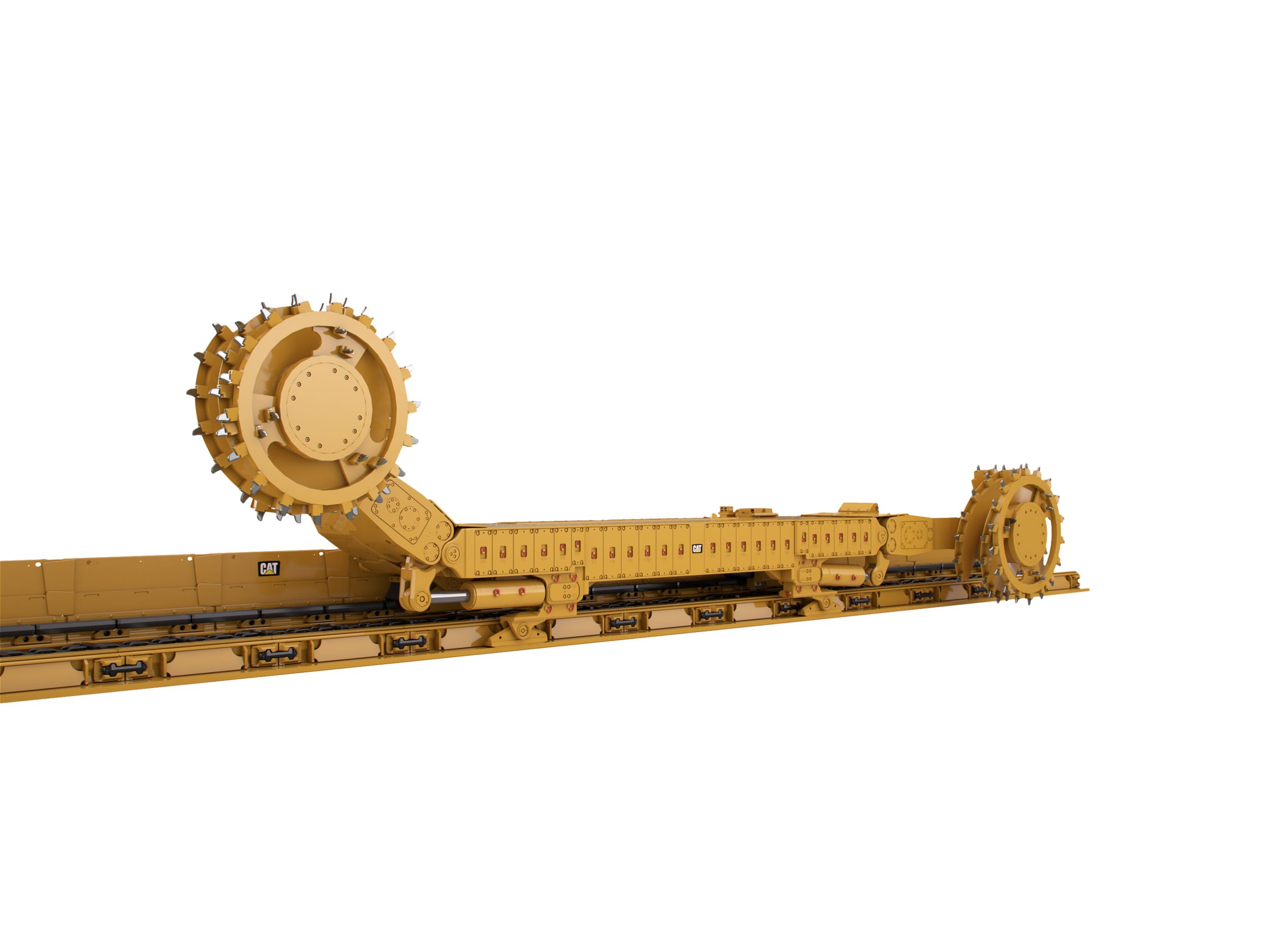

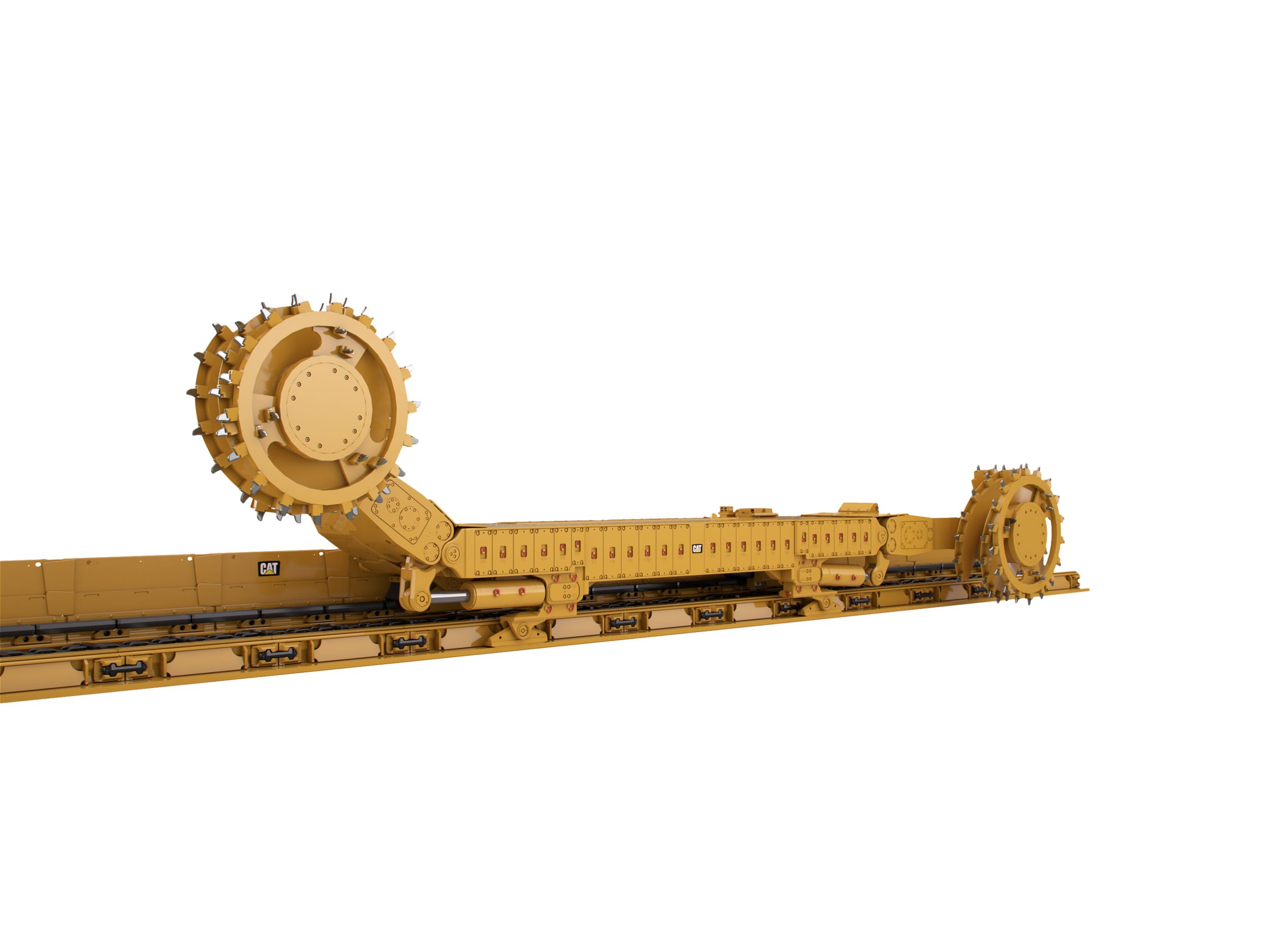

EL2000 Longwall Shearer

The EL2000 incorporates all the features and benefits that have been established with the Cat shearer range in a compact, rugged machine designed to meet the demands of high productivity in low- to medium-seam applications. The haulage system of the powerful EL2000 is tailored to the needs of high-productivity medium-seam applications with up to 125 kW (168 hp) AC drives.

Specifications

Product Brochures

Units:

Specifications

Seam Range

1.8-4.5 m (71-177 in)

Haulage Power

2 × 125 kW (2 × 168 hp) @ 50 Hz; 2 × 125 kW (2 × 168 hp) @ 60 Hz

Cutting Power

2 × 500 kW (2 × 671 hp) @ 50 Hz; 2 × 600 kW (2 × 805 hp) @ 60 Hz

Haulage System

AC

Coal Sizer

134 HP

100 kW

Body Height

20.5 in

520 mm

Haulage Speed

Up to 32 m/min (Up to 105 ft/min)

Operating Voltage

2300V, 3300V, 4160V

Installed Power

2548 HP

1900 kW

Typical Machine Length

45.1 ft

13.75 m

Applicable Minimum Pan Width

40.6 in

1032 mm

Machine Weight - Approximate

77 ton (US)

70 t

Pump Motor

67 HP

50 kW

Cutting Drum Diameter

1.40-2.30 m (55-91 in)

Haulage Pull

Up to 920 kN/206,824 lbf (Up to 91 tonnes/100 tons)

Height Range

1.80-4.50 m (71-177 in)

Available Haulage Motors

2 × 125 kW (2 × 168 hp)

Machine @ 50 Hz

Minimum Pan Width

40.6 in

1032 mm

Haulage System

AC inverter drive

Installed Power

Up to 1780 kW (Up to 2,387 hp)

Seam Range

1.8-4.5 m (71-177 in)

Available Cutting Power

2 × 500 kW (2 × 671 hp); 2 × 620 kW (2 × 831 hp); 2 × 750 kW (2 × 1,006 hp)

Pump Motor

40 HP

30 kW

Cutting Drum Diameter

1600-2500 mm (63-98.5 in)

Typical Machine Length - Drum Centers

46.15 ft

14065 mm

Machine Weight - Approximate

77 ton (US)

70 t

Operating Voltage

3300 V

3300 V

Haulage Power

2 × 125 kW (2 × 168 hp)

Haulage Speed (maximum) - High Downdrives

98.8 ft/min

30.11 m/min

Body Thickness

24 in

610 mm

Haulage Pull (maximum) - Low Downdrives

86.4 ton (US)

861 kN

Cutting Drum Speed - RA560

33.5, 38.8 and 43.8 rpm

Cutting Drum Speed - RA750

32.8, 37.4 and 45.2 rpm

Haulage Pull (maximum) - High Downdrives

90 ton (US)

897 kN

Haulage Speed (maximum) - Low Downdrives

102.9 ft/min

31.36 m/min

Machine @ 60 Hz

Seam Range

1.8-4.5 m (71-177 in)

Cutting Drum Diameter

1600-2500 mm (63-98.5 in)

Haulage System

AC inverter drive

Operating Voltage

4160 V

4160 V

Available Cutting Power

2 × 600 kW (2 × 805 hp); 2 × 740 kW (2 × 998 hp); 2 × 900 kW (2 × 1,207 hp)

Typical Machine Length - Drum Centers

46.15 ft

14065 mm

Machine Weight - Approximate

77 ton (US)

70 t

Pump Motor

48 HP

36 kW

Installed Power

Up to 2086 kW (Up to 2,797 hp)

Minimum Pan Width

40.6 in

1032 mm

Haulage Power

2 × 125 kW (2 × 168 hp)

Body Thickness

24 in

610 mm

Haulage Pull (maximum) - Low Downdrives

96.8 ton (US)

965 kN

Haulage Pull (maximum) - High Downdrives

100.8 ton (US)

1004 kN

Cutting Drum Speed - RA750

39.4, 44.9 and 54.2 rpm

Haulage Speed (maximum) - Low Downdrives

102.9 ft/min

31.36 m/min

Cutting Drum Speed - RA560

40.2, 46.6 and 52.6 rpm

Haulage Speed (maximum) - High Downdrives

98.8 ft/min

30.11 m/min

Powerpack - PP2

Type (1)

Single powerpack with less parts to fail and less tasks for quick and easy maintenance

Type (5)

For use with ISO 68 hydraulic oils

Type (2)

Fixed displacement pump (Standard) – Capacity at 50 Hz: 49 L/min (10.8 gal/min); Capacity at 60 Hz: 59 L/min (13 gal/min); Operating Pressure: 280 bar (4,060 psi). Fixed displacement pump (Option) – Capacity at 50 Hz: 62 L/min (13.6 gal/min); Capacity at 60 Hz: 74 L/min (16.3 gal/min); Operating Pressure: 225 bar (3,260 psi).

Type (7)

Reliable low-voltage pump motor rating of 30 kW @ 50 Hz (48 hp @ 60 Hz)

Type (3)

Robust hydraulic reservoir of 140 L (37 gal) capacity

Type (4)

Integral monitoring transducers (oil level and temperature)

Type (6)

Available with 6 section valve bank

Type (8)

Optional boost valve for accelerated gate end operations (recommended for cowls)

Electrical Control Box - ECB2

Type (2)

High current carrying capacity of 400 amps; accommodation of trailing cables up to 120 mm² (4/0 AWG)

Type (5)

Containing cutter motor contactors, circuit breakers, control transformer, current monitoring, HV fuses, earth leakage and visible disconnect

Type (3)

Internal chassis can be ‘bench built,’ tested and stored

Type (1)

This flameproof module contains most of the shearer electrical control and power distribution components.

Type (4)

LV circuit breakers resettable through FLP cover (reduced downtime) Powerful PMC Evo-S control system with state-of-the-art Ethernet communication

Haulage Transformer Box - HTB2

Type

Flameproof module containing the main 253 kVA haulage transformer, power supplies, auxiliary transformer, drive system circuit breaker, hydraulic pump motor, and a 250 kW (335 hp) 600V AC inverter drive with integrated regenerative breaking.

Electrical Material

Type (2)

All electrical material is designed and certified to IEC standards and also complies with other regional and national standards, such as MSHA, GOST, MA, ATEX and DGMS, as well as Australia’s New South Wales and Queensland regulations.

Type (1)

This model of shearer is available with headlights, cameras, methane monitoring, end displays and audible alarms.

Hydraulic Material

Type (2)

The hoses are assembled to Hose Assembly Standard DIN 20066.

Type (1)

All hose assemblies are to ISO 6805 and proof tested according to EN ISO 1402.

Type (3)

Hose selection and routing per industry standard best practices (including MDG41, ISO TS 17165N2 and SAE J1273)

Type (4)

Cat® hoses are aligned with the standards of MSHA, DGMS and MA

Water Material

Type (4)

Cat hoses are aligned with the standards of MSHA, DGMS and MA. MDG 41 compliant hoses are available for Australia.

Type (3)

Hose selection and routing per industry standard best practices (including MDG41, ISO TS 17165N2 and SAE J1273).

Type (2)

The hoses are assembled to Hose Assembly Standard DIN 20066.

Type (1)

All Cat hose assemblies are designed according to ISO 6805 and proof tested according to EN ISO 1402.

Type (6)

Onboard water filtration (optional)

Type (5)

Stainless steel fittings (optional)

Health Monitoring

Type

A comprehensive health monitoring system is available, including oil levels and temperatures, flows, pressures and vibration analysis.

Machine Automation and Communication

Type (3)

Fast Ethernet Broadband communication allows enhanced diagnostics and analysis

Type (8)

Pan Angle Measurement System (PAMS) enabling fully automated gate end cutting sequences without machine operator interactions (optional)

Type (2)

Modular design allows individual configuration (from basic monitoring and protection to advanced automation) to meet customer requirements

Type (7)

Shearer automation levels available:

– Standard Machine Control

– Basic Automation

– Advanced Automation (including face alignment horizon control)

– Standard Machine Control

– Basic Automation

– Advanced Automation (including face alignment horizon control)

Type (9)

Horizon Control from PMC-R Controls to allow corrections to Floor and Roof drum cutting heights (optional)

Type (4)

Control system architecture with backup functionality

Type (10)

Shearer Remote Operation to allow machine control from a safe remote location outside the face (optional)

Type (1)

Distributed, high-performance PMC-S control system for machine control, health monitoring, system protection and predictive maintenance

Type (6)

Machine performance algorithm “advanced motor and speed control” for increased machine uptime, coal production and longer service life

Type (5)

Widespread use of intrinsically safe components for improved serviceability and maintenance

Ranging Arms - RA750

Type (7)

Available cutter motors – 620 kW and 750 kW at 50 Hz (998 hp and 1,207 hp at 60 Hz)

Type (6)

Maximum drum diameter of 2500 mm (98 in)

Type (8)

Robust cowl drive mechanism (optional)

Type (1)

Reconfigurable gear cassettes for adaptation of drum speeds

Type (4)

Transmission rating of 750 kW at 50 Hz (1,207 hp at 60 Hz)

Type (3)

Quillshaft transmission protection

Type (5)

Separate oil compartments for high speed and planetary section (optimal cooling and lubrication)

Type (9)

Vibration monitoring (optional)

Type (2)

Integral monitoring transducers

Mainframe - MF2

Type (4)

Modular design enabling for selective overhauls

Type (2)

Maximum protection of electrical boxes, providing the highest level of flameproof integrity, protects gearboxes against torsion

Type (3)

Split mainframe is available in case of transportation limitations

Type (1)

High structural integrity and absorption of all cutting and haulage forces, providing maximum protection for all major units

Type (5)

Spray boom retrofittable

Type (6)

Mainframe add additional weight to cope with the most challenging cutting conditions

Dimensions (Approximate) - Low

AFC Pan Width - Minimum

41 in

1032 mm

Diameter - Shearer Cutting Drum

63 in

1600 mm

Machine Height - Over Main Body

58 in

1467 mm

Clearance from Drum to AFC Toeplate

12 in

300 mm

Ranging Arm Cutting Drum Diameter

63 in

1600 mm

Height - Top of Machine Main Body

58 in

1467 mm

AFC Pan Width - Maximum

53 in

1342 mm

Cutting Height - Minimum

71 in

1800 mm

Ranging Arm Length - Hinge to Drum

111 in

2815 mm

Distance Between Ranging Arm Hinge Points

332 in

8435 mm

Maximum Cutting Drum Overall Width

45 in

1150 mm

Cutting Height - Maximum

155 in

3930 mm

Shearer Drum Undercut of Floor

16 in

400 mm

Distance Between Drums with Arms Horizontal

554 in

14065 mm

Vertical Tunnel Clearance

24 in

600 mm

Distance Between Trapping Shoe Centers

252 in

6398 mm

Dimensions (Approximate) - Mid-Low

Clearance from Drum to AFC Toeplate

12 in

300 mm

Distance Between Trapping Shoe Centers

236 in

5985 mm

Machine Height - Over Main Body

60 in

1518 mm

Distance Between Drums with Arms Horizontal

554 in

14065 mm

Ranging Arm Cutting Drum Diameter

75 in

1900 mm

AFC Pan Width - Maximum

53 in

1342 mm

Ranging Arm Length - Hinge to Drum

111 in

2815 mm

Maximum Cutting Drum Overall Width

45 in

1150 mm

Distance Between Ranging Arm Hinge Points

332 in

8435 mm

Vertical Tunnel Clearance

26 in

651 mm

Shearer Drum Undercut of Floor

20 in

500 mm

Diameter - Shearer Cutting Drum

75 in

1900 mm

AFC Pan Width - Minimum

41 in

1032 mm

Cutting Height - Maximum

163 in

4130 mm

Cutting Height - Minimum

75 in

1900 mm

Height - Top of Machine Main Body

60 in

1518 mm

Dimensions (Approximate) - Mid-High

Vertical Tunnel Clearance

28 in

700 mm

Distance Between Trapping Shoe Centers

258 in

6541 mm

Maximum Cutting Drum Overall Width

45 in

1150 mm

Cutting Height - Maximum

170 in

4330 mm

Shearer Drum Undercut of Floor

24 in

600 mm

Height - Top of Machine Main Body

62 in

1567 mm

Ranging Arm Length - Hinge to Drum

111 in

2815 mm

Diameter - Shearer Cutting Drum

87 in

2200 mm

Distance Between Ranging Arm Hinge Points

332 in

8435 mm

Clearance from Drum to AFC Toeplate

12 in

300 mm

Distance Between Drums with Arms Horizontal

554 in

14065 mm

Ranging Arm Cutting Drum Diameter

87 in

2200 mm

AFC Pan Width - Minimum

41 in

1032 mm

AFC Pan Width - Maximum

53 in

1342 mm

Cutting Height - Minimum

87 in

2200 mm

Machine Height - Over Main Body

62 in

1567 mm

Dimensions (Approximate) - High

Clearance from Drum to AFC Toeplate

12 in

300 mm

Ranging Arm Length - Hinge to Drum

111 in

2815 mm

Distance Between Trapping Shoe Centers

236 in

5985 mm

Cutting Height - Minimum

98 in

2500 mm

AFC Pan Width - Maximum

53 in

1342 mm

Shearer Drum Undercut of Floor

26 in

670 mm

Diameter - Shearer Cutting Drum

98 in

2500 mm

Maximum Cutting Drum Overall Width

45 in

1150 mm

Height - Top of Machine Main Body

65 in

1647 mm

Vertical Tunnel Clearance

31 in

780 mm

Distance Between Ranging Arm Hinge Points

332 in

8435 mm

AFC Pan Width - Minimum

41 in

1032 mm

Machine Height - Over Main Body

65 in

1647 mm

Ranging Arm Cutting Drum Diameter

98 in

2500 mm

Cutting Height - Maximum

180 in

4560 mm

Distance Between Drums with Arms Horizontal

554 in

14065 mm

Ranging Arm

RA560 (9)

Vibration monitoring (optional)

RA560 (6)

Maximum drum diameter of 2000 mm (79 in)

RA560 (3)

Quillshaft transmission protection

RA560 (4)

High-speed gears and idlers rated for 560 kW at 50 Hz (900 hp at 60 Hz), hub rated for 750 kW at 50 Hz (1,200 hp at 60 Hz).

RA560 (8)

Robust cowl drive mechanism (optional)

RA560 (7)

Available cutter motor – 500 kW at 50 Hz (805 hp at 60 Hz)

RA560 (5)

Separate oil compartments for high speed and planetary section (optimal cooling and lubrication)

RA560 (2)

Integral monitoring transducers

RA560 (1)

Reconfigurable gear cassettes for adaptation of drum speeds

Haulage Unit - HU150

Type (8)

Quillshaft transmission protection

Type (9)

Machine parking brake (optional)

Type (2)

Transmission rating of 150 kW (200 hp) providing designed redundancy

Type (6)

Haulage unit accepts hydraulic motor for installation and face recovery

Type (1)

Haulage motor limited to 125 kW (168 hp)

Type (4)

Absolute encoder for accurate machine position detection (no reset devices at gate ends needed)

Type (3)

Transmission reduction of 137:1

Type (5)

Closed loop control for accurate load-sharing and increased service life of rackbar and sprocket

Type (7)

Oil temperature monitoring

Type (10)

Vibration monitoring (optional)

Dust Suppression

Available Solutions

Wide range of dust suppression solutions available:

– Body sprays

– Spray booms

– Sloughing plate sprays

– Spray rings (in place of cowls)

– Shearer clearers

– Body sprays

– Spray booms

– Sloughing plate sprays

– Spray rings (in place of cowls)

– Shearer clearers

Remote Control

Type (2)

Color graphic display

Type (3)

Tilt, drop and impact detection

Type (1)

Lightweight handheld device

Downdrive

Type (4)

Transmission rating of 125 kW (168 hp) for low downdrives/150 kW (200 hp) for high downdrives

Type (1)

Configurable for direct and indirect drives

Type (5)

Trapping shoe with replaceable wear inserts (for indirect drives), safe and easy to replace

Type (7)

Reconfigurable downdrive and shoe posts for different pan widths and seam heights

Type (3)

Designed for superior serviceability with quick and easy access for maintenance (Higher variants use cartridge design for top drive wheel assembly/lower versions provide access via top cover)

Type (6)

Suitable for all rack type systems

Type (2)

Fully removable, modular gearbox

Standard Equipment

Brochures